Known as "industrial teeth",tungsten carbide tools are widly used in wire industry.Some of tungsten carbide wire tools are used directly with tool holders,such as tungsten carbide rollers,tungsten carbide descaling rolls, some of them are welded or mounted on steel case as finished carbide wire tools,such as tungsten carbide wire drawing dies, tungsten carbide nail dies,etc.After devoting to carbide wire tools for more than 10 years,Oston Carbide has mature experience on designing and manufacturing of carbide wire tools supplying,we encourge you to have a further talk with us if you can't find the part on our web,please feel free to contact us by phone or by email.

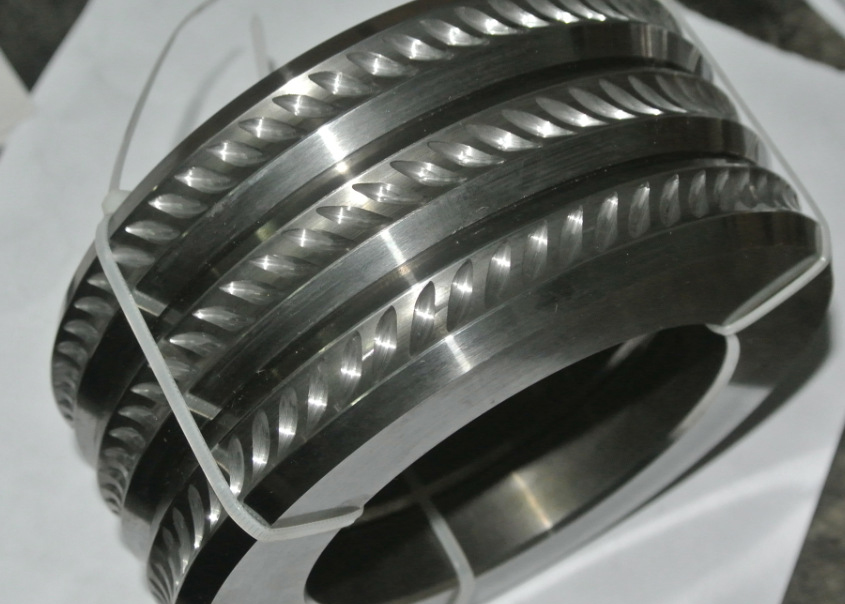

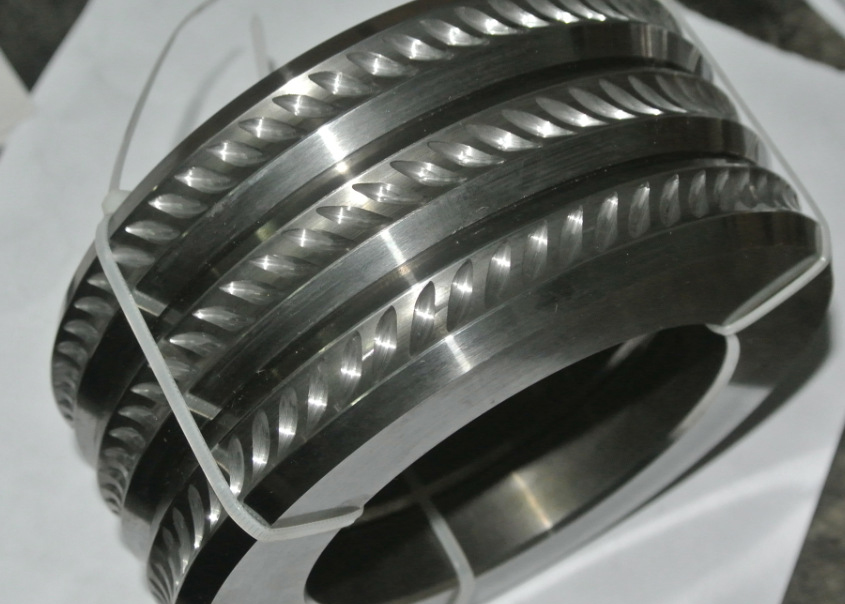

1.Tungsten Carbide Rollers for Cold Rolling Mill

Tungsten carbide rollers,also called as tungsten carbide wire mesh rolls,is applied in reinforcement wire cold rolling and forming mills in construction industry,thread steel bars are with the durability 10 to 20 times higher compared to common steel roller,and the surface quality and the steel bar size accuracy are greatly improved.

Oston tungsten carbide rollers are produced by isostatic suppressing and HIP sintering,which are the most advanced facilities to ensure the stable properties,which reduces the production cost and improves the rebars quality with high precision on dimension,clear ribs and beautiful surface.

T.C roll is one of Oston leading carbide products, we owned molds of all standard carbide roller dimensions including:

Φ123*Φ82*15mm-RO/RT/FO/CA/PR

Φ125*Φ82*15/20mm-RO/RT/FO/CA/PR

Φ145*Φ95*16/18mm-RO/RT/FO/CA/PR

Φ150*Φ95*15/16/18/22mm-RO/RT/FO/CA/PR

Φ150*Φ90*15/16/20/22mm-RO/RT/FO/CA/PR

Φ180*Φ125*15/16/18mm-RO/RT/FO/CA/PR

Φ200*Φ90*15/16/20/22mm-RO/RT/FO/CA/PR

Customized dimensions are also more than welcome here with even 1 PC testing quantity,please feel free to contact us if you have any need on carbide products.

2.Tungsten Carbide wire straightening and descaling rolls

Wire descaling and straightening is a necessary process in steel plant before rolling mill, tungsten carbide descaling rolls are important accessories for mechanical descaling of entry rod in reduction mills for clean purpose,steel descaling rolls were used in the past and they were replaced by tungsten carbide descaling rolls gradually.

Knowns as "Hard alloy",tungsten carbide has obvious advantages compared with too stell rolls,including ultra wear resistance,high impact strength,high temperatuer resistance,corrosion resistance. The service time of tungsten carbide rolls is 12-15 times than that of steel rolls.

Tungsten carbide rolls can be devided into types as below according to the specific purpose:

Wire Descaling Roller

Wire descaling rolls can be made in tungsten carbide material or tool steel material and are used for mechanical descaling of entry rod in reduction mills.

Wire Stress-relieving Roller

Wire stress-relieving Rolls also can be made in T.C. material or tool steel material ,they are used to improve the mechanical property of the cold rolling wire.

Wire Straightening Roller

Wire straightening roll is a important component for wire straightening machine,and its main function is to eliminate unwanted curvature caused by winding wire or rod into coils or onto reels before further process.

3.Wire Drawing Dies

Tungsten carbide wire drawing dies are tools with highly-polished, specially-shaped holes through which wire is drawn to reduce its diameter. They have a metal case and a tungsten carbide nib.PCD wire drawing dies are made from metal case and a polycrystalline diamond nib, a synthetic material that provides superior resistance to cracking and wear.

Drawing parameters include measurements such as inlet diameter, bell radius, entrance angle, approach angle, bearing, and back relief. Elongation, the ratio of length after drawing to the length prior to drawing is also an important consideration when choosing wire drawing dies.

When selecting tungsten carbide wire drawing dies, wire material and drawing parameters are important specifications to consider,main wires are:

- low carbon steel wires

- middle carbon steel wires

- high carbon steel wires

- stainless steel wires

- copper wires

- silver wires

- galvanized high-carbon steel

Wire drawing dies are used with a variety of wire drawing tools and equipment. Straight wire drawing machine is one of the most common metal wire processing equipments,it can draw high carbon,medium carbon and low carbon steel wire, stainless steel wire, copper wire, alloy copper wire, aluminum alloy wire, etc.

wire drawing dies plays an important role in the wire drawing process,PCD wire drawing dies are often used for thin wires,and it is also trendy choice too in recent years bec of its good performance,tungsten carbide wire drawing dies are always used to draw thicker wires and application where PCD dies are too expensive.