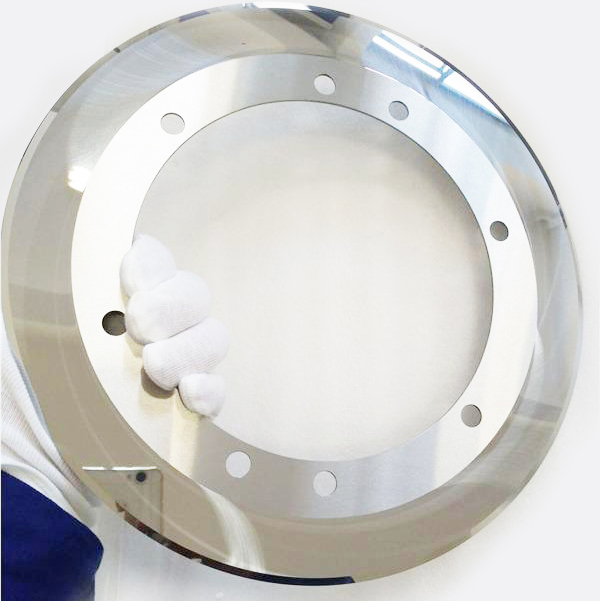

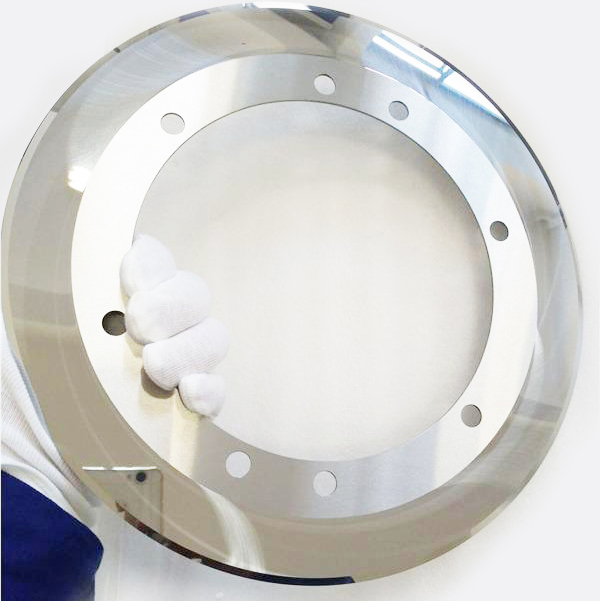

Tungsten Carbide Circular Blades

Tungsten carbide circular blades are widely used in packaging industry, Li-ion battery industry,Metal sheet industry,Tabacco & Cigarette Industry,optical fiber industry printing industry and capacitor industry.

Oston carbide slitting blades are produced from premium tungsten carbide material by hot isostatic pressing equipment.High parallelism and flatness after finishing ensures the high cutting quality without runout.Currently we supply full dimensions of carbide corrugated cutters for machines brands including:

BHS,Fosber,Agnati,Marquip,Peters,Hsieh,Mitsubishi,Justu,TCY,Champion,Mingwei,Isowa,

Kaituo,Jinshan,etc.Tin coating is available for Oston carbide circular slitters,we encourage you to contact us for further information.

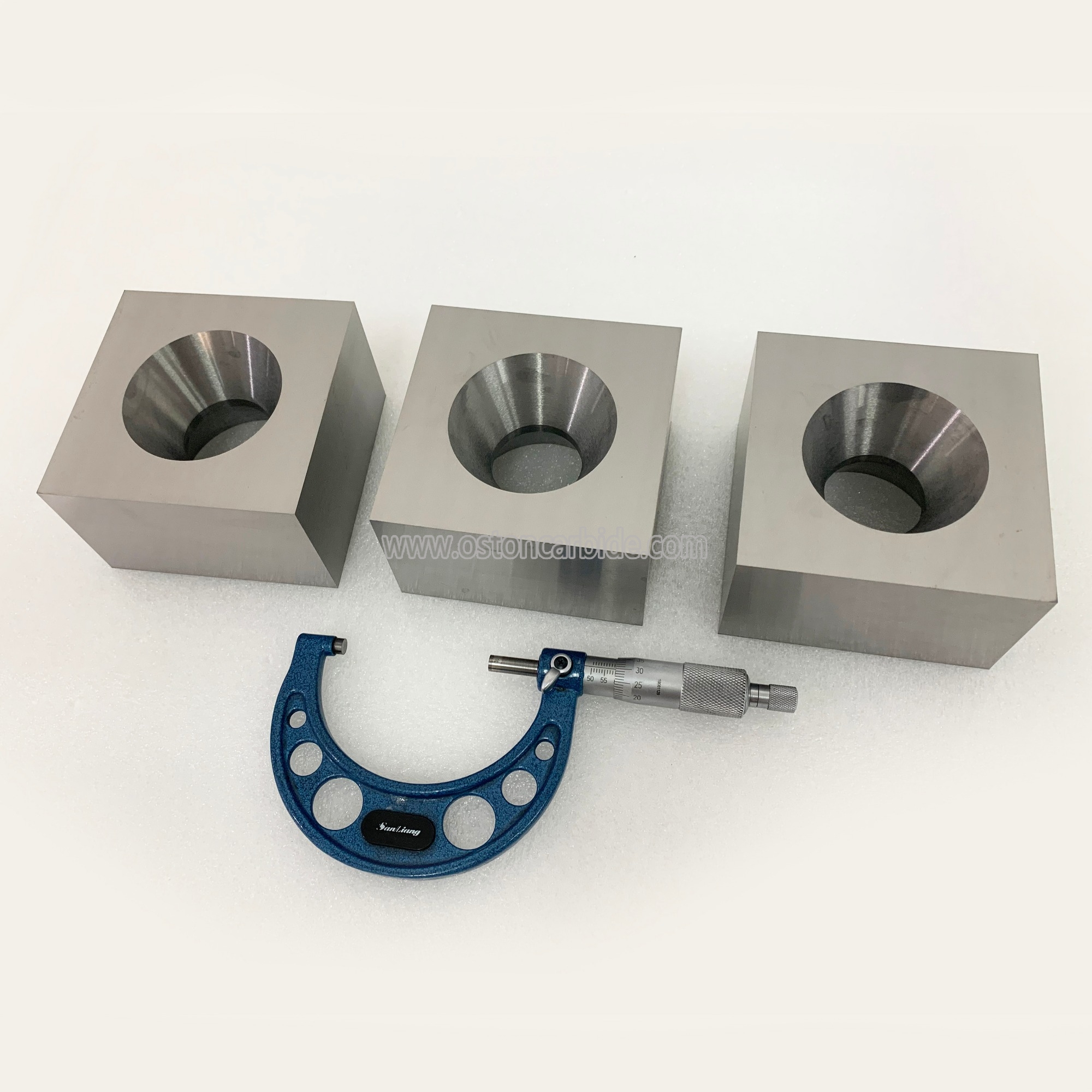

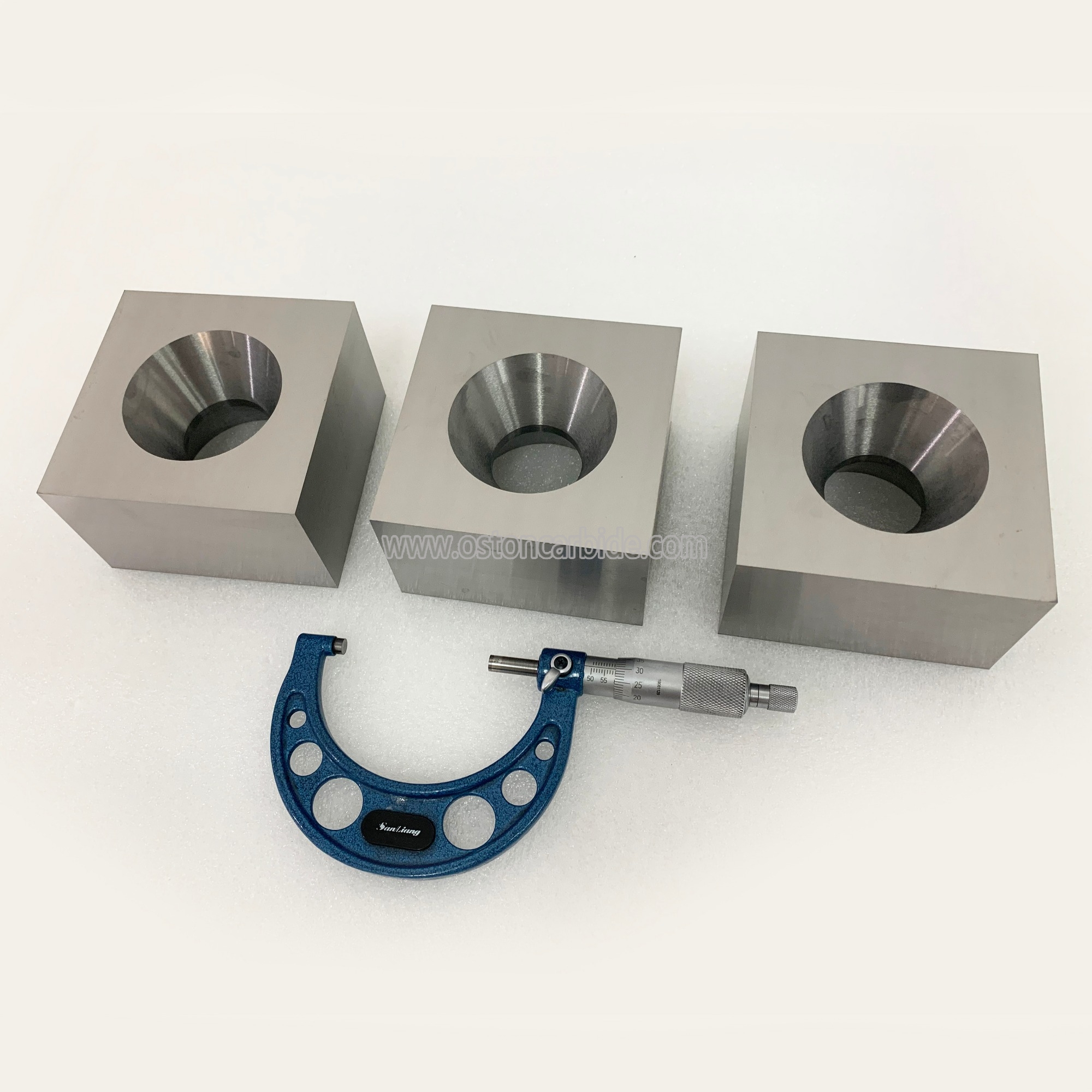

Tungsten Carbide Shredder Blades

Tungsten carbide shredder blades are tungsten carbide replaceable knives for shredder machine,there are circular blades,Cube blades and rectangular blades according to the shredder model and the process that carbide blades are applied.

Tungsten Carbide,D2,M2,SKD11,1.2379, DC53 are different materials usually used for Shredder blades according to shreddered materials and processes. Tungsten carbide is the toughest material for the toughest process,they are also used for some stiff wasted material such as metal,wasted tyres,electronic circuit board,,plastic waste,wood and other large-volume waste.

The shredder blade directly affects the service life and production efficiency of the shredder,the benefits of tungsten carbide shredder blades include:

-Ultra wear resistance and impact strength.

-High efficiency in tough applications,in which steel blades may not work.

-Excellent durability of the cutting edge for long service life.

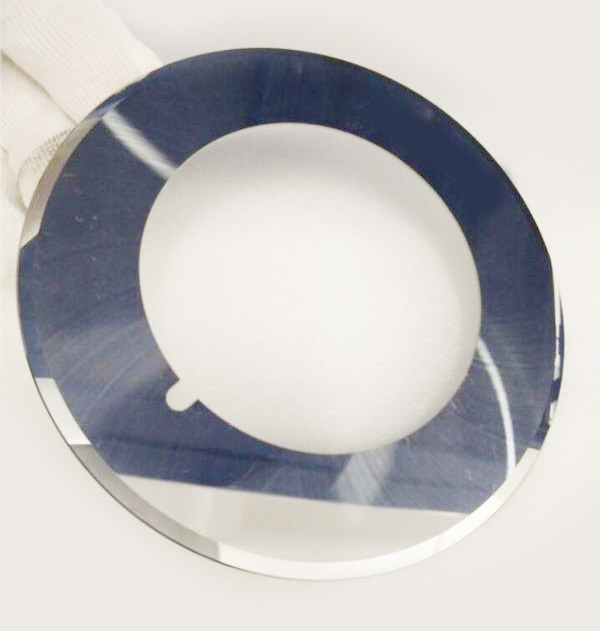

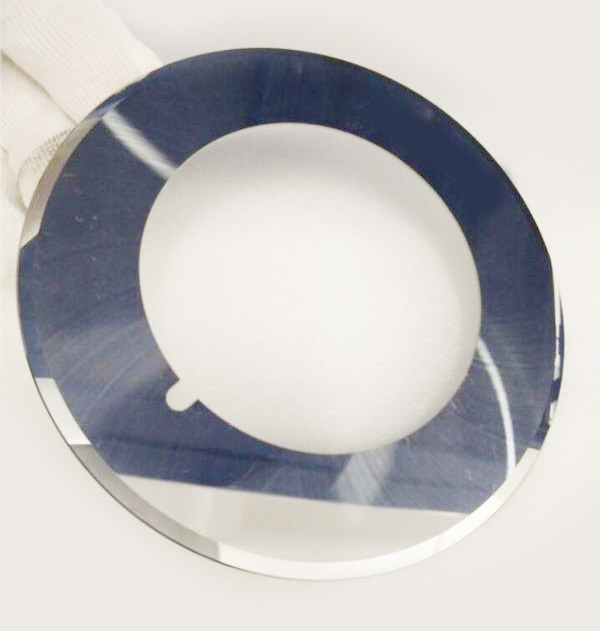

Tile Cutter Wheels

Manual tile cutter is a kind of popular tile cutting tool,tile cutter wheels are replacement blades of manual tile cutter,they are made from tungsten carbide,which is durable with excellent wear resistance. The surface finish of tile cutter wheel can divided into general grinding and mirror polishd too, currently we supply TiAlN coating(black) and Tin coating(golden) for the surface,which could increase 15%-20% on service life.

Compared with electric cutting machine,advantages of manual tile cutter wheel are :

1. Fast cutting speed: one cutting is completed in a few seconds;

2. Good cutting effect: the straight line precision is high, and the edge is smooth;

3. Low cutting cost: one bearing cutter wheel can cut 30,000 to 50,000 meters;

4. No electricity, no water, no noise, no dust;

5. The operation is simple, convenient and safe.